Energy producers are always looking for ways to do things safer, faster, cheaper, and smarter, especially in the current market. Automation is the key here and we are working hard to put this technology to work for all of our solutions across the board. We already showed you how accurate water data can prevent major problems (and headaches, and money loss) during the completions process. Today we’re going to show you how using this technology can save you money daily, through increased personnel utilization.

The problem

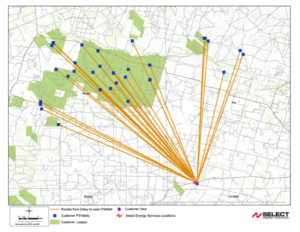

An independent energy producer had over 40 water assets in the Eagle Ford Shale. In order to maintain completion schedules, the operator needed to know with certainty how much water each asset had available for use at any given time. Based on the average drive time from the operator’s field office to the water asset, the distance between each source, and the average time it took to measure each, the producer determined that a single employee could only reach 11 assets each day. This meant they would need to hire three full-time employees in order to receive ONE accurate reading on each water asset daily.

The solution

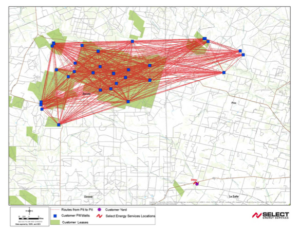

Select was able to automate the energy producer’s water monitoring process with AquaView®, a full suite of water monitoring technologies. First, Select deployed a hydrographic mapping vessel to each asset to build an initial map, assess volume, and water quality. The HMV is equipped with sonar, GNSS, and compass technology to provide a complete view of water assets. It’s also strong and nimble enough to navigate environments ranging from flowback pits to tight tree-filled water sources. Next, a remote pit monitor (RPM) was installed on each of the 40 water assets. RPM units send data to a secure, online portal up to every 30 minutes. Each unit is connected to the portal via satellite to ensure accuracy and reliability, even in the most remote locations.

The result

With AquaView®, the energy producer was able to remotely monitor all of their water assets and receive accurate volume and quality data for each source on demand. The automated system allowed them to save money and increase employee utilization. They also reduced the chances of safety incidents by reducing the amount of time their team members spent driving each day.